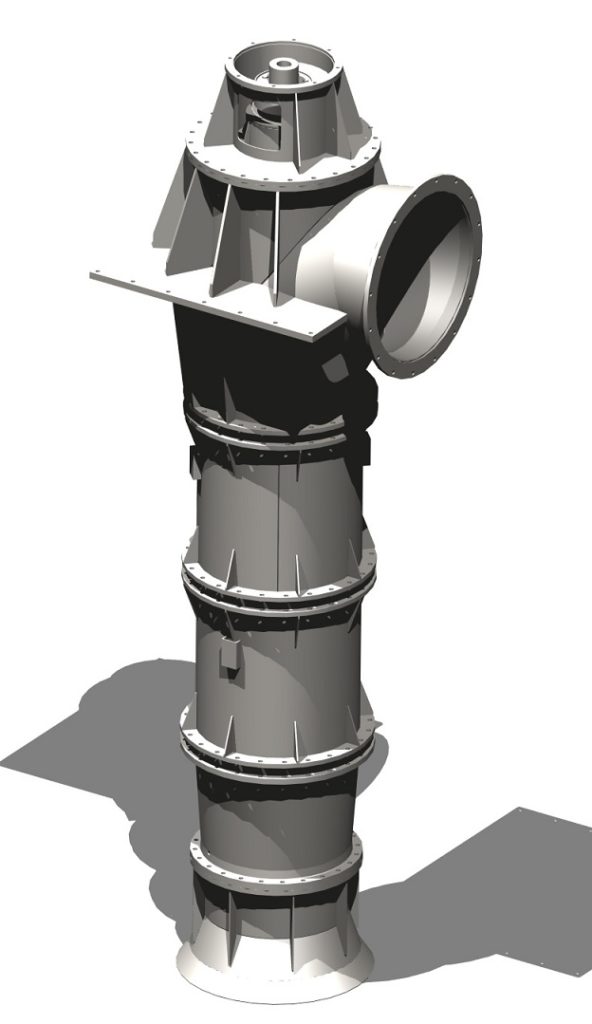

MULTISTAGE PUMP - MS, DMS, MSTD, MSS

The MS are process duty multistage centrifugal pumps in ring section design, designed and produced for moderate to high pressure heads available in five basic sizes. The suction and pressure bodies can be rotated for 90° in both directions, which enables the pumps to be mounted and adapted to the requirements of the installation. Axial thrust is relieved by means of a drum mounted on the shaft inside the discharge hull, rest of the trust bears one of the roller bearings. The impellers are centrifugal of closed type identically fixed to a shaft, supported on two roller bearings.

Shaft sealing:

The shaft sealing could be arranged by: soft packing or mechanical seal.

In soft packing arrangements the shaft is protected by replaceable, stainless sleeve while the stuffing box is furnished with lantern ring for introduction of cooling liquid into the packing.

On special demand the pumps could be furnished with mechanical seal in accordance with the characteristics of the liquid and the operating conditions.

Drive:

- Electric motor;

- Diesel motor.

Arrangements:

Multistage type of pumps could be arranged in:

- Horizontal version MS, DMS, MSTD;

- Vertical version MSS, VMS;

- Cooling system MSTD.

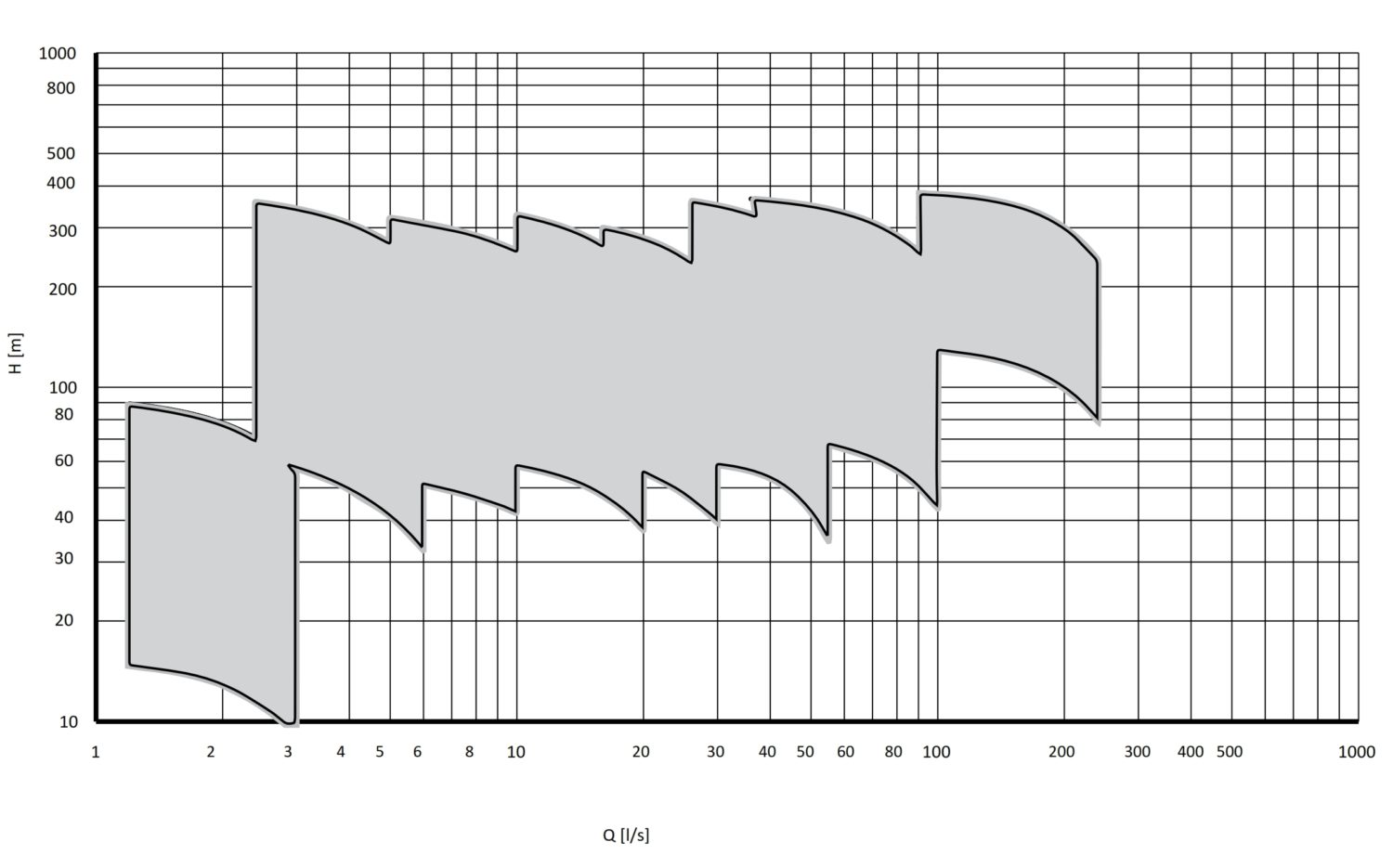

Technical data:

- Capacity: up to 240 l/s;

- Head: up to 370 m;

- Pump size: up to DN 200;

- Temperature: up to 160 °C.

Applications:

- Water supply pumps, irrigation and drainage pumps in agriculture, water circulation pumps;

- Mining and civil engineering;

- Industrial and process services;

- Transport of thin oils, petroleum products;

- Chemical and process industry.

Advantages:

- This MS pumps achieve very high pressure ≈ 30m / impeller;

- Suction and discharge flanges can be rotated for 90° to conform with the pipeline;

- One way of balancing the axial thrust in MS pumps is to arrange the impellers in opposite direction, another way of balancing the axial thrust is to use a balancing drum, the rest of the axial force is beared by roller bearings.

Pos. Component Material 1 Pump Case Cast Iron 2 Impeller Cast Iron, Bronze 3 Shaft Stainless steel 4 Shaft sleeve Hardened Stainless steel Optional materials: Cast iron (Gray, Ductile), Cast steel, SS (AISI 304, 316), Duplex SS, Super duplex SS, Bronze, AI, or other on customer request. Event Calendar

Jan Feb Mar Apr

May Jun Jul Aug

Sep Oct Nov DecCUSTOMER VALUES

After-Sales service

Our prime goal – to make our customers’ equipment work more efficiently and trouble-free.

Each product – susceptible to installation and commissioning by a specialized work team;REFERENCE

STRABAG AG Subsidiary STABAG Skopje, PS Udovo, Macedonia

Production and delivery of 4 (four) Propeller pump aggregates units for the needs of Pump Station Udovo – Macedonia for transport of clean water.Why you should contact us?

In the decision process of choosing an adequate representative company we will be evaluating several criteria: its reputation on the specific market, sales organization and after sales service capability, use of promotional and communications tools, the financial strength and size of the company, the existence of physical facilities and willingness to carry inventories, and the trading areas covered and the compatibility of represented companies with our product range.Address:

Str. Pero Nakov No.126, 1000 Skopje, Republic of MacedoniaTel:

+389 (0)2 254 98 17

Fax:

+389 (0)2 254 98 33Contact:

info@pumpi.com.mk

www.pumpi.com.mk

Copyrights © 2024

Menu