Magnet Pump – KMP

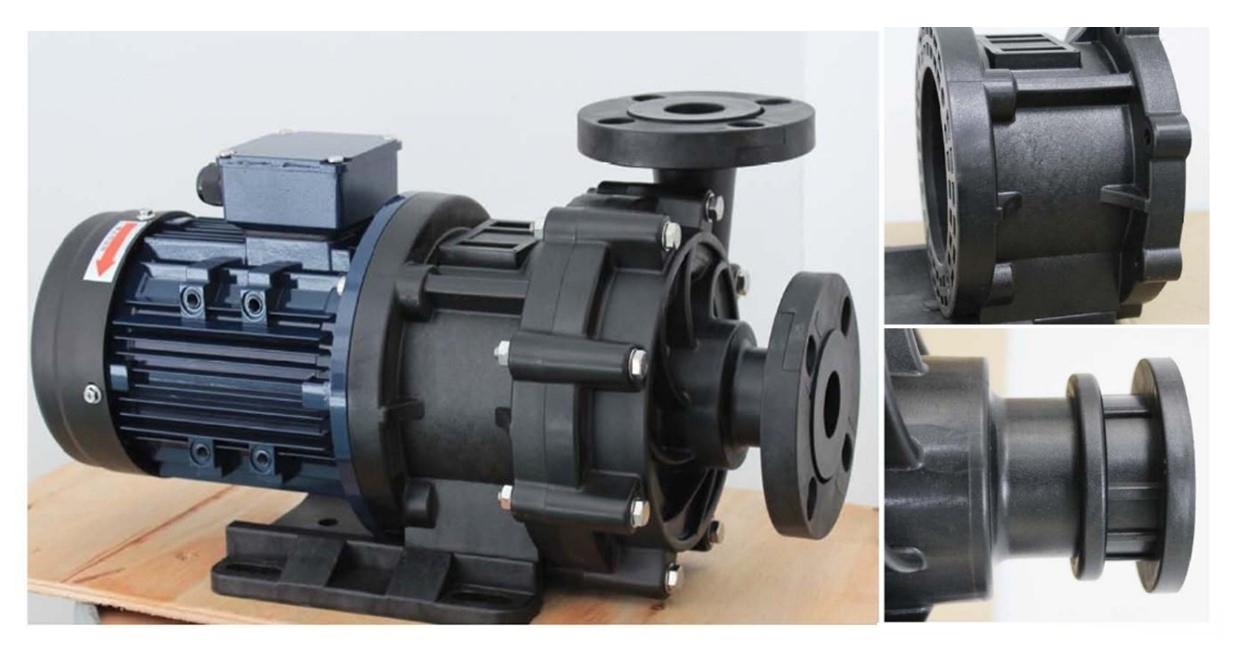

Plastic magnetic Pump features

1.No-contact structure.

Precisely setting the position of the passive magnet and active magnet. Even in Idling, bearing will not contact with the rear thrust ring. Inhibits the frication heat and ensures the lubrication.

2.Compact and strong.Light shape and internal parts standardization, easy maintenance. Pump body with reinforcing ribs, strength and excellent pressure resistance

3.Innovative design, no leakage.

Front cover newly designed, union type connection is convenient, no leakage. One-piece design impeller, high efficiently and quietly.

4.Upgrade the self-circulation cooling structure.

Except Impeller and magnet capsule with heat dissipation hole, Shaft sleeve and magnet capsule also with heat dissipation hole which can make the liquid around the pump shaft and bearing circulate under the action of centrifugal force and impeller. Dissipate the heat by friction, avoid deformation and melting.

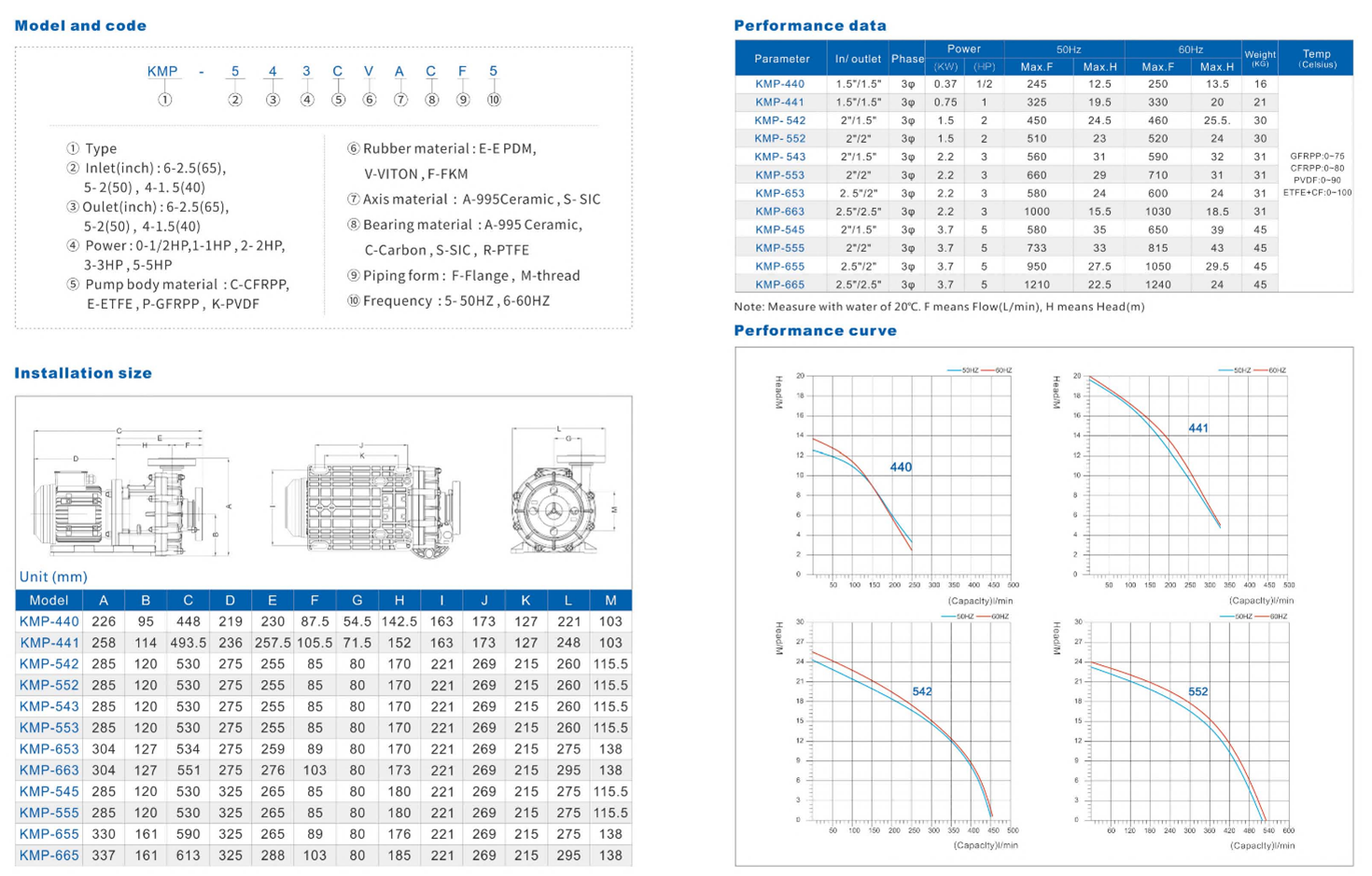

Performance data

Model | In/outlet (Inch) | Power (Hp) | 50HZ | 60HZ | ||

Max.F(l/min) | Max.Head(m) | Max.Head(m) | Max.Head(m) | |||

KMP-440 | 1.5″/1.5″ | 1/2 hp | 245 | 12.5 | 250 | 13.5 |

KMP-441 | 1.5″/1.5″ | 1 hp | 325 | 19.5 | 330 | 20 |

KMP-542 | 2″/1.5″ | 2 hp | 450 | 24.5 | 460 | 25.5 |

KMP-552 | 2″/2″ | 2 hp | 510 | 23 | 520 | 24 |

KMP-543 | 2″/1.5″ | 3 hp | 560 | 31 | 590 | 32 |

KMP-553 | 2″/2″ | 3 hp | 660 | 29 | 710 | 31 |

KMP-653 | 2.5″/2″ | 3 hp | 580 | 24 | 600 | 24 |

KMP-663 | 2.5″/2.5″ | 3 hp | 1000 | 15.5 | 1030 | 18.5 |

KMP-545 | 2″/1.5″ | 5 hp | 580 | 35 | 650 | 39 |

KMP-555 | 2″/2″ | 5 hp | 733 | 33 | 815 | 43 |

KMP-655 | 2.5″/2″ | 5 hp | 950 | 27.5 | 1050 | 29.5 |

KMP-665 | 2.5″/2.5″ | 5 hp | 1210 | 22.5 | 1240 | 24 |