Menu

SPLIT CASE DOUBLE SUCTION PUMP-D

Horizontal Split Case Double Suction Centrifugal Pumps D are engineered to pump clean water or low viscosity clean liquids at moderate heads more economically than any other type of pump. All fabricated parts are standardized and accurately machined for true alignment, increasing overall durability. Impellers are statically and dynamically balanced and constructed with double inlets, practically eliminating the axial thrust and resulting in high operating efficiency.

Shaft sealing:

The shaft sealing could be arranged by:soft packing or mechanical seal.

- In soft packing arrangements the shaft is protected by replaceable, stainless sleeve while the stuffing box is furnished with lantern ring for introduction of cooling liquid into the packing.

- On special demand the pumps could be furnished with mechanical seal in accordance with the characteristics of the liquid and the operating conditions, including the possibility of sealing with cartridge mechanical seal.

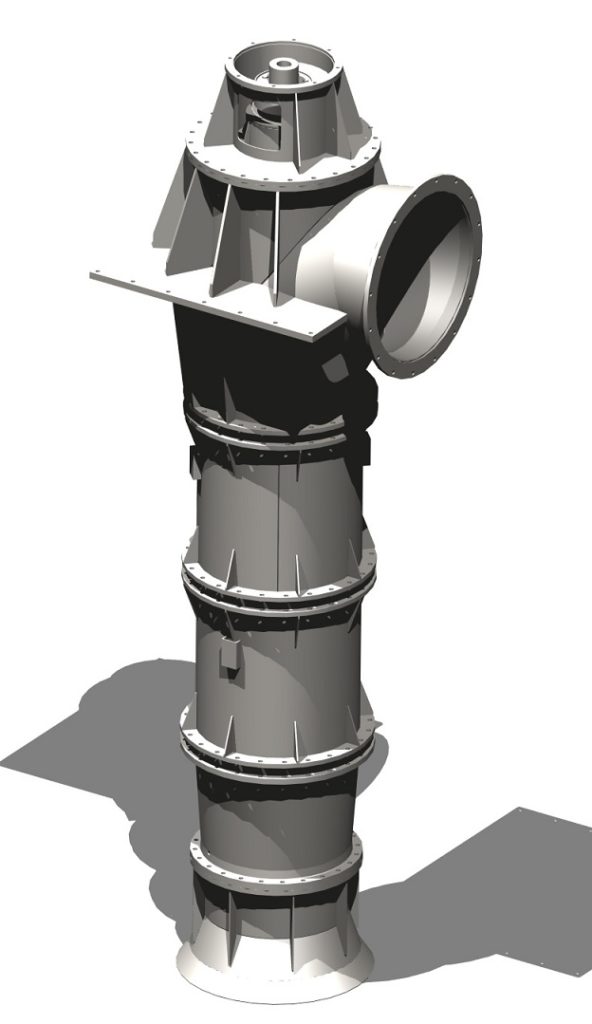

Arrangements:

Split Case Double Suction Pumps Type D could be arranged in:

- Horizontal arrangement;

- Vertical Arrangement.

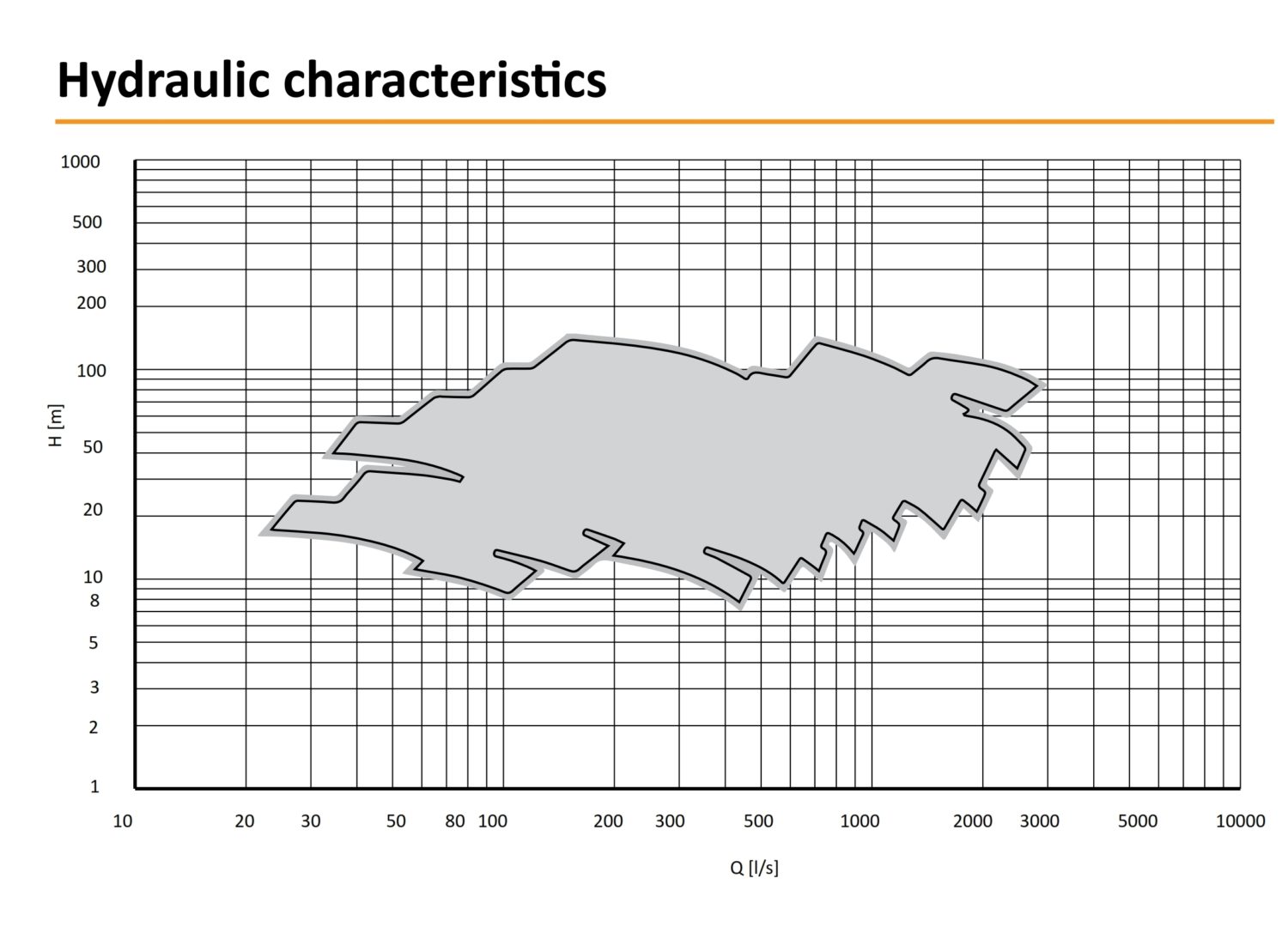

Technical data:

- Capacity: up to 2500 l/s;

- Head: up to 140 m;

- Pump size: up to DN 600;

- Temperature: up to 90°C

Applications:

For liquid transfer and circulation of cold clean or slightly polluted water.

Typical applications in:

- Municipal water supply;

- Power plants;

- Industrial plants;

- Boiler feed and condensate systems;

- Irrigation and dewatering;

- General purposes etc.

Drive:

- Electric motor;

- Diesel motor.

Advantages:

- Single stage, medium pressure double inlet centrifugal pump with two flanged bearing frame, suitable for flexible coupling to electric motor or internal combustion engine as a driver.

- Ample dimensioned shaft guided through roller bearings and hardened shaft sleeve.

- Fully-enclosed single piece casting, double inlet impeller practically doesn’t produce any axial trust. – High operating reliability due to maintenance and Service parts;

- Spiral housing axially splitted means easy maintenance without pipe disconnection.