SELFPRIMING MULTISTAGE CENTRIFUGAL PETROL TRANSFER PUMPS- BCP

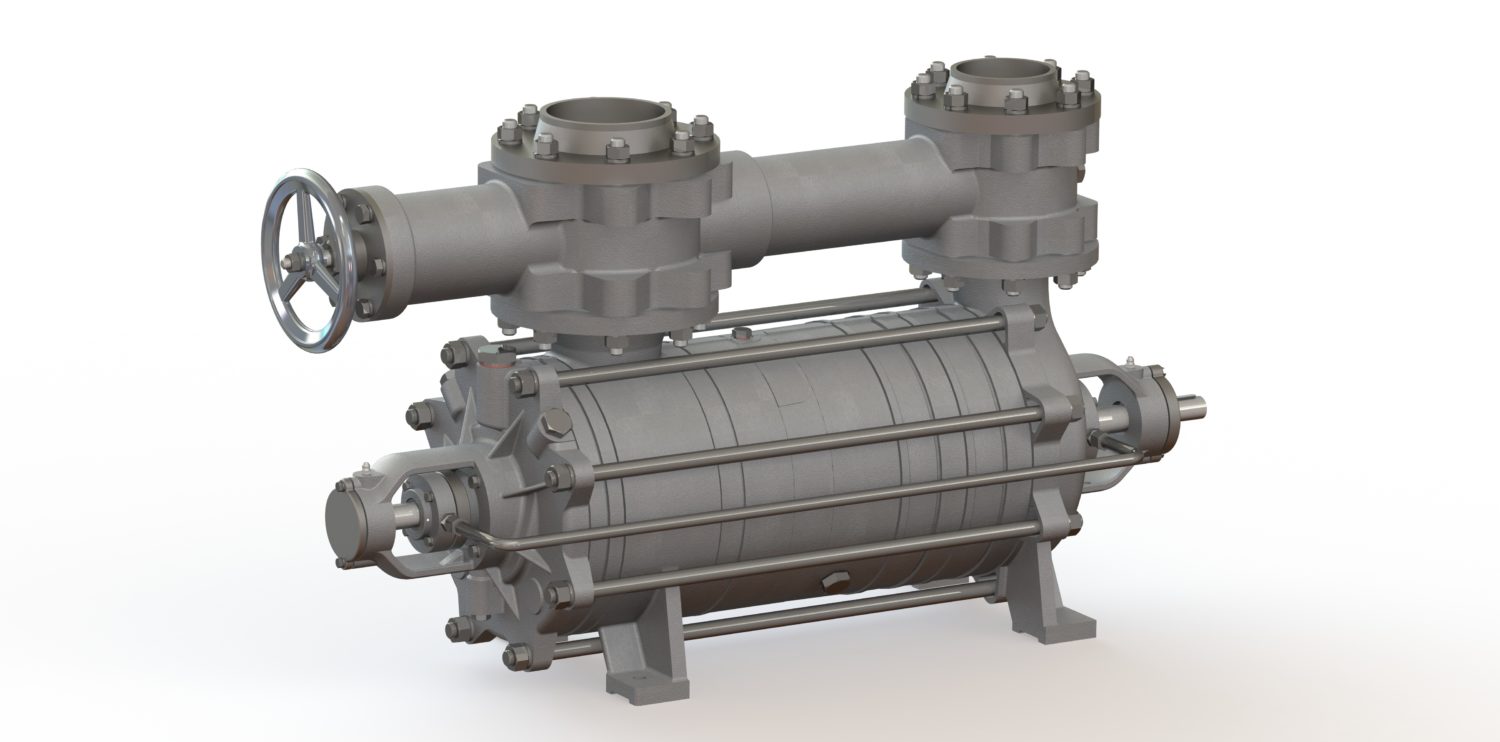

BCP petrol pumps are centrifugal, self priming, horizontal pumps. They are assigned for transport of all kinds of petrol and naphtha. They also could be used for transport of ammonia, benzol etc. BCP pumps are designed as a single stage and multistage. They can be driven by electric drive on the same base plate. Self priming of the pump is made possible by means of the vacuum rotor which is enclosed in the pump.

Shaft sealing:

Shaft sealing is an important element, with the BCP pumps, mechanical seals are applied, which are very suitable for easily evaporable fluid packing. The principle of mechanical seals operation is based on contact impermeability between two perfectly smooth surfaces. One of them is immovable and other rotates together with shaft. The resting force on the contact surfaces is realized by means of a spring.

This elastic connection ensures a good packing. The seals are cooled by the transport fluid and the realized connections between the seals.

Drive:

- Electric motor;

- Diesel motor.

Technical data:

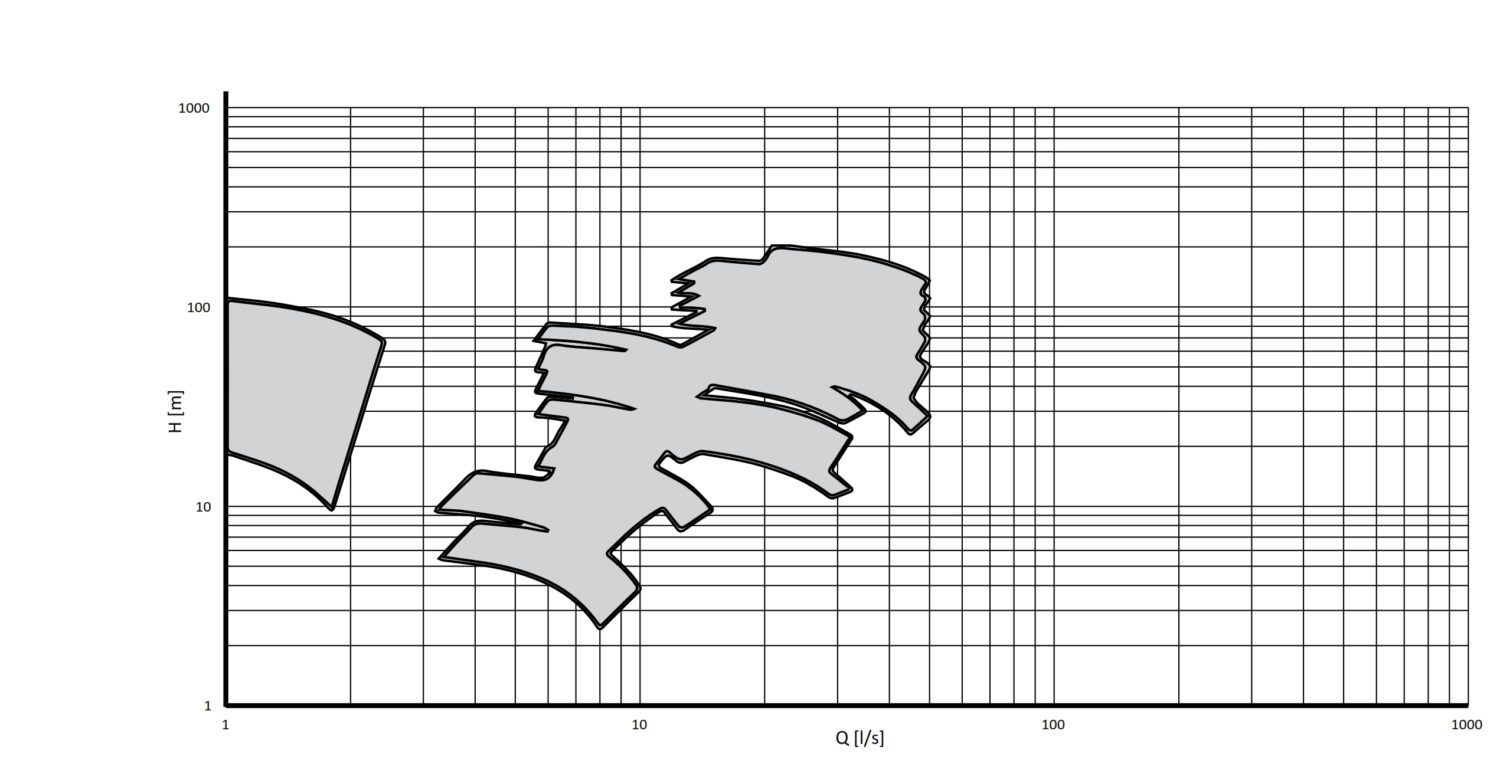

- Capacity: up to 50 l/s;

- Head: up to 200 m;

- Pump size: up to DN 125;

- Temperature: up to 40°C.

Applications:

The BCP pumps are intended for pumping of volatile fluids saturated with air and steam without mechanical contaminants. Fluids that may be pumped include: petrol, naphtha, ammonia etc.

Main fields of application:

- Loading and discharging of tankers and lorry tanks;

- Refinery process pump;

- Petrol storage tanks.

Advantages:

- BCP pumps are self priming with cavity impeller and relief valve for protection of the pipeline from high pressure.

| Pos. | Component | Material |

|---|---|---|

| 1 | Pump Case | Cast Iron |

| 2 | Impeller | Bronze |

| 3 | Shaft | Stainless steel |

| 4 | Shaft sleeve | Stainless steel |

| 5 | Bearing bracket | Cast Iron |

| 6 | Pump cover | Cast Iron |

| Optional materials: Cast iron (Gray, Ductile), Cast steel, SS (AISI 304, 316), Duplex SS, Super duplex SS, Bronze, AI, or other on customer request. | ||