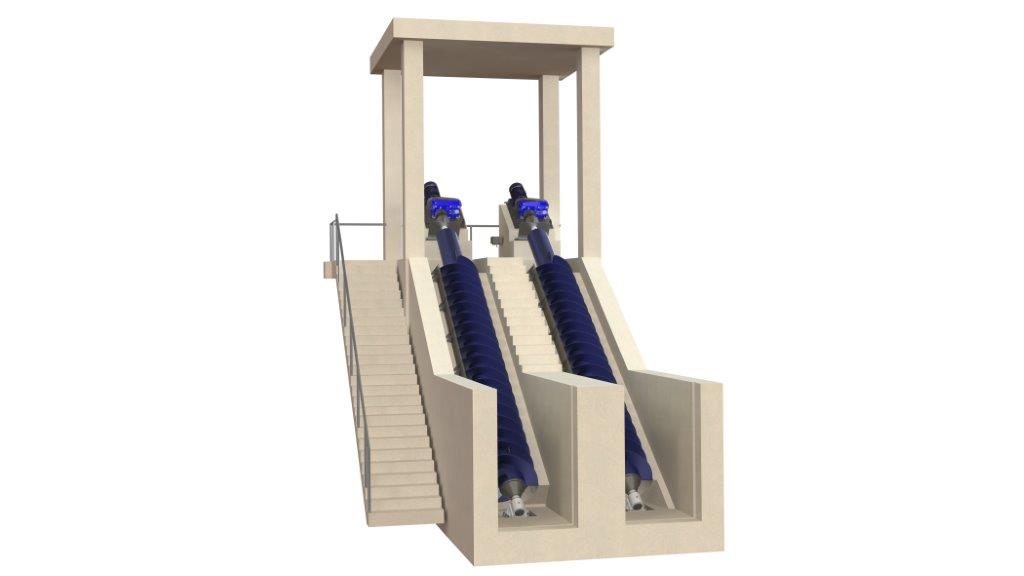

ARCHIMEDEAN SCREW PUMP

Archimedean spiral pumps are designed for pumping sludge and polluted liquids without their pretreatment. The principle of operation of these pumps is by rotating of the blades to transport the medium to a higher level. Large passages make the Archimedean pumps possible to handle with solid liquids without any danger of a blockage in the process. One of the main benefits of these pumps is inability to cause a cavitation and since they are operated on a low speed there is almost no efficiency loss.

Depending on what type of water is being transported, the life time of these pumps can be from 30 to 40 years.

Pump components:

- Driving unit

Depending on the required features there can be made different drive-unit arrangements. The standard drive-unit consists electric motor connected to the reduction gearbox which is connected with the upper bearing of the screw pump.

- Upper Bearing

The upper bearing main role is to accommodate axial and radial forces. This bearing is designed as a self-aligning roller bearing.

- Lower Bearing

The lower bearing housing flange is connected to the screw body. Main role of the lower bearing is to accommodate only radial loads. During the operation this bearing is lubricated with grease by the automatic lubricator. The lower bearing is hermetically sealed for protection from the liquids.

- Screw

The screw has the most important role, by rotating the screw lifts and transports the medium at higher levels. Screw body is usually made from longitudinally or spirally wound steel tubes.

Advantages:

- Simple and Robust Construction, open, Clog-Free;

- Easy Maintenance and Low Operational Costs;

- Pump Capacity is Self-regulated as a function of incoming flow;

- Long Operational Lifetime(30-40 years);

- High Efficiency (Up to 85 %);

Arrangements:

Screw Pump in a Concrete Trough, where the screw, suspended between the upper and lower bearing, rotates free from the trough with a minimal gap of few millimeters.

Technical data:

Inclination angle: 30° 35° 38°

Scra w diameter [mm]: 3000 3000 3000

Capacity [l/s]: 3130 2513 2170

Head [m]: 8.8 10.2 10.9

Applications:

Archimedean screw pumps offer wide application possibilities:

Typical applications are:

- Waste water treatment:

- Drainage;

- Rainwater;

- Flood water;

- Industrial process water;

- Domestic sewage.

- Irrigation projects;

- Water supply;

- Land drainage;

- Reclamation of wetlands.

Materials and coating:

Screw pumps can be produced from coated steel or stainless steel.

| Item | Application | System | Thickness in µ |

|---|---|---|---|

| Standard | Activated sludge | Send blasting SA 2,5 Epoxy coating | 2 x 150 |

| Auto cure | Waste water | Send blasting SA 2,5 Zink primer Epoxy coating | 1 x 40 2 x 150 |

| Heavy Duty | Sand & Particles | Send blasting SA 2,5 Zink primer Sealer Epoxy coating | 1 x 40 1 x 40 2 x 150 |

| Cover coating | H2S occurrence | Send blasting SA 2,5 Epoxy special coating | 2 x 175 |

Optional materials: Cast iron (Gray, Ductile), Cast steel, SS (AISI 304, 316), Duplex SS, Super duplex SS, Bronze, AI, or other on customer request. | |||