OIL TERMINAL-PLOCE CROATIA

Project:

The Main objective of the Project was Servicing of old pumps by change of all vital parts, assembly of new parts and putting of all serviced pump into operation. All of the serviced pumps were old more than 30 years, and by this servicing their life was prolonged for additional 10 years. Totally 16 pumps were serviced and covered by ATEX Certification. Also, this project covered purchase of 5 New Pumps, with provided specifications below.

The complete Equipment was intended for use potentialy Exprosive Atmosphere, and was delivered by satisfying the requirements of ATEX Directive 2014/34/EU, Directive for non-electrical equipment of Category 2.

Brief description:

The main objective of the project was capital rehabilitation of Oil Terminal Ploce, by purchasing of 5 new Pump Aggregates and Servicing of 16 pumps. The realized activities comprised Design, Manufacturing, Delivery and Putting into Operation of existing and new pumps.

Realized activities:

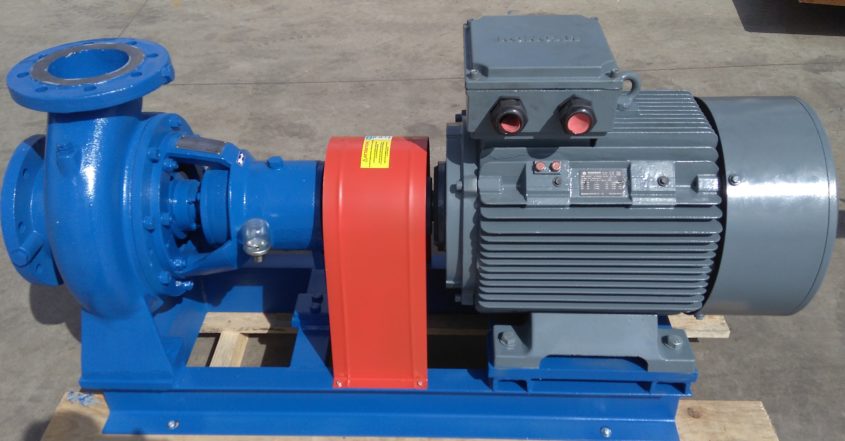

- Production and delivery of 2 (two) End Suction Centrifugal Pumps Type: S20CP31 for transport of oil, with the following characteristics:

- Q=420 [m3/h]

- H=25 [m]

- N=55 [kW]

- n=1450 [RPM]

- Sealing: Mechanical Seal

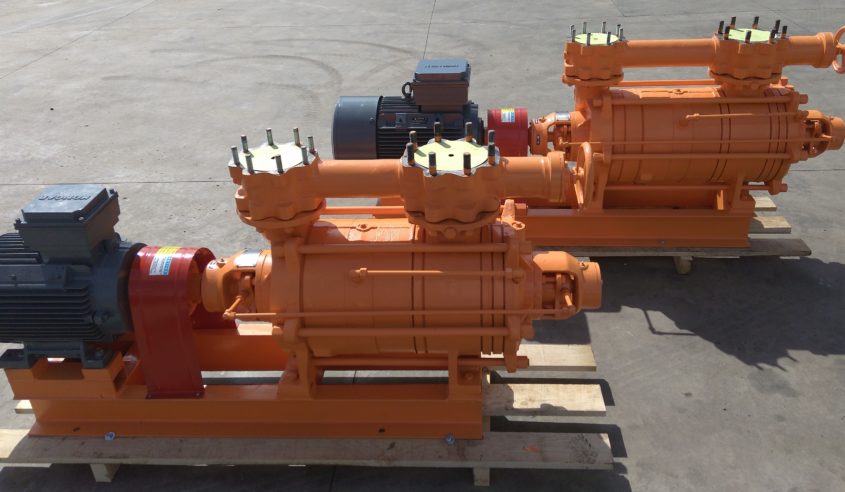

- Production and delivery of 2 (two) Selfpriming centrifugal Petrol- Transfer pumps type: BCP150-1; BCP150-2 for transport of oil, with the following characteristics:

- Q=20 [l/sek] Q=78 [m3/h]

- H=30 [m] H=50 [m]

- N=18.5 [kW] N=30 [kW]

- n=1450 [RPM] n=1450 [RPM]

- Sealing: Mechanical Seal

- Production and delivery of 1 (one) Vertical pumps aggregate type: Vc4-2 for transport of oil, with the following characteristics:

- Q=4 [l/sek]

- H=50 [m]

- N=7.5 [kW ]; n=2900 [RPM] with Mechanical Seal

Please contact us for more details!